|

Hangseng(Ningbo) Magnetech Co.,Ltd

|

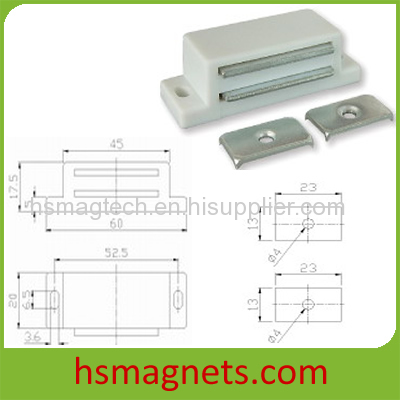

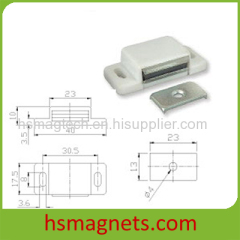

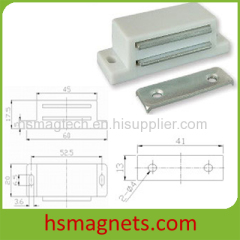

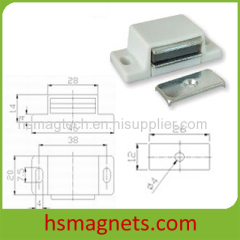

White Magnetic Door Catcher & Holder

| Price: | 0.01~100.0 USD |

| Payment Terms: | T/T,L/C,WU;PAYPAL |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

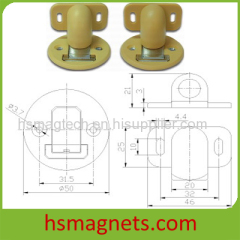

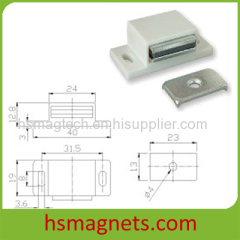

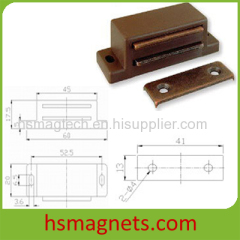

Magnetic door stopper

With clamp magnets,used for all types of doors

High quality,low price,fast delivery

Easy to fix doors

The door catcher

HSMAG Magnets produces NdFeB permanent magnets in a modern factory in China. Our magnets are produced powder metallurgically by sintering. The process starts from the hydrogen decrepitation and fine milling of the raw material. The resulting powder is then compressed into the wanted shape and in the same time its particles are aligned using a magnetic field. The compressed blocks are sintered and machined into the final dimensions before coating and magnetizing.

Quality inspection at each manufacturing step together with highly automated production provides a stable and well-controlled process, high yield and homogenous products.

Our subsidiary uses magnet blocks produced at our factory in Ningbo. HSMAG Magnets Ningbo has capabilities to slice big magnet blocks into small magnets, typically used in the sensor applications. Thickness of the smallest magnets can be below 1 mm. Our subsidiary has its own coating line and quality inspection. Today, magnet elements like the ones used in wind power generators can also be assembled by HSMAG Magnets Ningbo.

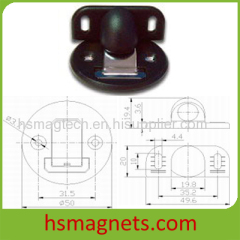

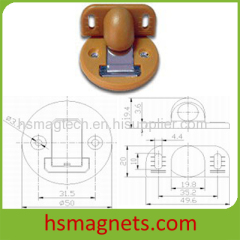

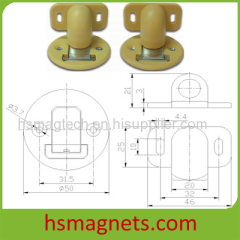

magnetic door catcher

1. high intensity, various shapes

2.Grade: N35-N52,(M,H,SH,UH,EH)

3.Plating: Ni,Zn etc

Specification:

Product name: Permanent magnetic door catcher

1.Grade: N33, N35, N38, N40, N42, N48, N50, N52 (M, H, SH, EH, UH,AH)

2.Shape: Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more. Customized Design (Design proper magnets for clients specific requirements)

3.Coating: Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chemical, PTFE, Parylene, Everlube, Passivation and more.

4.Maximum Working Temperature:

N35-N52, 80°C(176°F)

35M-50M, 100°C(212°F)

35H-48H, 120°C(248°F)

35SH-45SH, 150°C(302°F)

33UH-40UH, 180°C(356°F)

33EH-38EH, 200°C(392°F)

28AH-35AH, 220°C(428°F)

5.Tolerance:

+/-0.05mm for small dimensions,

+/-0.1mm for common specifications,

+/-0.15mm for big blocks

6. Directions of Magnetization:

a. Axially Magnetized

b. Diametrally Magnetized

c. Radial Magnetized

d. Multi-poles magnetized

e. Customzied specific requirements magnetized

Application:

magnetic door catcher use widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, VCMs in hard disk drives, printer, switchboard, loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, common daily use, and so on.

PCT:130c ,humidity 100%,vapor pressure 2.7 bar.20 days,average low weight loss less than 2 mg/cm2

Common Applications :

Sensors Linear actuators Microphone assemblies Magnetic separators DC and servo motors Speakers Printers Magnetic hooksComputer rigid disc drives Beam controls Intelligent toys MRI/NMR

We are specialized in producing NdFeB Magnet over many years,We guarantee the best price based on the same quality and service. Our finance conditiearon and industrial reputation are excellent.

Testing Center

We are ISO/TS16949:2002 certified and well implement all procedures strictly under control. Problem preventive actions and quality assurance are preoperly combined with special inspection for all procedures from raw material purchasing ,outside cooperating part manufacturing,inside manufacturing to shipping . We also install a complete set of physical and chemical test equipment to make sure that all our products are manufactured and shipped under strictly quality control .

Salt Spray Test :

Mainly test the surface treatment against the corrosion. Usually the tested samples will be continuous sprayed 24 hours in the 35℃ temperature to see if there is any rust appearance on the surface.

Projection Instrument:

Mainly test the magnets with irregular shapes such as arc segments and any other irregular-shaped parts to see if their dimensions meet the customers' requirements or not.

PCT Instrument:

Mainly test the magnets to prevent against corrosion on the high temperature and high atmospheric pressure . Usually the test condition is 120℃ temperature and 2 atmospheric pressure .

Heat& Humidity Instrument:

Mainly test the magnet to against corrosion on certain temperature and humidity . Usually the test condition is 80℃ temperature and 90%+/-3% humidity

Hysteresgraph:

Mainly test the magnetic characteristics of the magnet, including Residual (Br ), Coercive(Hcb) . Intrinsic Coercive(Hcj), Max. Energy product(BH max) and any other related magnetic parameters.

HSMAG Magnets has been supplying high quality Neodymium Magnets to customers for about 20 years.

Super Magnet

Made of neodymium, the most powerful magnet material in the world

Great for projects that require extreme strength in a small size

Permanent magnetism guaranteed

Not for children