|

Hangseng(Ningbo) Magnetech Co.,Ltd

|

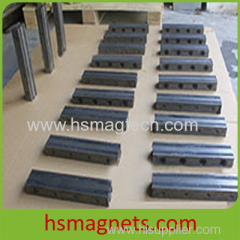

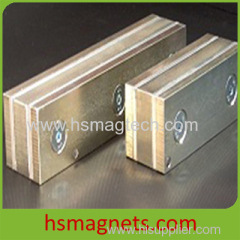

Shuttering Magnets Solutions for Pre-cast concrete formwork

| Price: | 0.01~100.0 USD |

| Payment Terms: | T/T,L/C,WU;PAYPAL |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

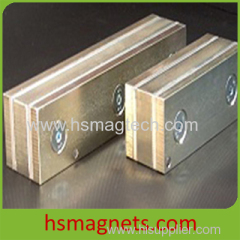

SHUTTERING MAGNETS and MAGNETIC SYSTEMS

range of SHUTTERING MAGNETS and MAGNETIC SYSTEMS for the Pre-cast Concrete Industry are compact and light

SHUTTERING MAGNETS and MAGNETIC SYSTEMS

range of SHUTTERING MAGNETS and MAGNETIC SYSTEMS for the Pre-cast Concrete Industry are compact and lightweight. Thanks to the use of modern magnetic materials, Shuttering systems offer an extraordinary magnetic power compared to the minimum weight of the products themselves.

The product range can be adapted for use in any concrete formwork applications.

The magnetic systems can be used on any formwork surfaces of ferrous metal materials.

Shuttering systems can create and adapt various systems in any dimensions to fulfill the applications and requirements of our customers.

Magnetic formwork system is designed to produce flat concrete products of any shape up to 600 mm. With the use of magnetic formwork concrete products, significantly reduces installation time and reduces the final cost of production.

KEY BENEFITS OF SHUTTERING MAGNETS:

1. Reducing the complexity and time of the installation of formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece products of all forms on the same steel table.

3. Eliminates the need for welding, shuttering magnets does not damage the steel table.

4. Makes it possible to produce radial products.

5. A small cost of a set of magnets. The average payback of about 3 months.

6. The main advantage of the shuttering magnets is that you do not need to have a lot of different forms for different products, you need to have a set of magnets, adapters for different height boards and steel table.

PCT:130c ,humidity 100%,vapor pressure 2.7 bar.20 days,average low weight loss less than 2 mg/cm2

Common Applications :

Sensors Linear actuators Microphone assemblies Magnetic separators DC and servo motors Speakers Printers Magnetic hooksComputer rigid disc drives Beam controls Intelligent toys MRI/NMR

We are specialized in producing NdFeB Magnet over many years,We guarantee the best price based on the same quality and service. Our finance conditiearon and industrial reputation are excellent.

Testing Center

We are ISO/TS16949:2002 certified and well implement all procedures strictly under control. Problem preventive actions and quality assurance are preoperly combined with special inspection for all procedures from raw material purchasing ,outside cooperating part manufacturing,inside manufacturing to shipping . We also install a complete set of physical and chemical test equipment to make sure that all our products are manufactured and shipped under strictly quality control .

Salt Spray Test :

Mainly test the surface treatment against the corrosion. Usually the tested samples will be continuous sprayed 24 hours in the 35℃ temperature to see if there is any rust appearance on the surface.

Projection Instrument:

Mainly test the magnets with irregular shapes such as arc segments and any other irregular-shaped parts to see if their dimensions meet the customers' requirements or not.

PCT Instrument:

Mainly test the magnets to prevent against corrosion on the high temperature and high atmospheric pressure . Usually the test condition is 120℃ temperature and 2 atmospheric pressure .

Heat& Humidity Instrument:

Mainly test the magnet to against corrosion on certain temperature and humidity . Usually the test condition is 80℃ temperature and 90%+/-3% humidity

Hysteresgraph:

Mainly test the magnetic characteristics of the magnet, including Residual (Br ), Coercive(Hcb) . Intrinsic Coercive(Hcj), Max. Energy product(BH max) and any other related magnetic parameters.

HSMAG Magnets has been supplying high quality Neodymium Magnets to customers for about 20 years.

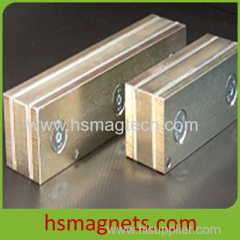

Super Magnet

Made of neodymium, the most powerful magnet material in the world

Great for projects that require extreme strength in a small size

Permanent magnetism guaranteed

Not for children